All Rights Reserved Performance Associates Coachworks & Customs 2014 Made With Serif WebPlus.X6

So much work done on the shop floor is really tribal.

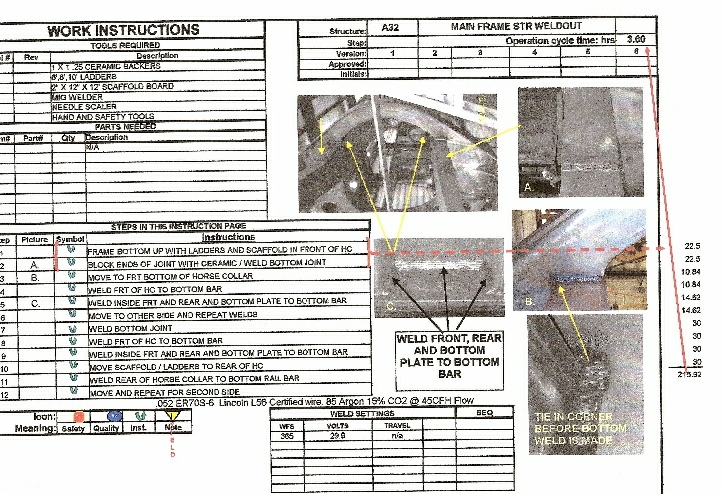

The person doing methods writes up a procedure that he feels is the proper way of doing an operation and posts it to the shop floor but, invariably, after about four or five structures, the shop floor develops it’s own way of doing things.

A new weldor is hired for the job and they either must learn from the shop floor how to do the job or develop their own system.

The instructions have long ago been thrown away.

How can you control quality, consistency, production, shipping dates, and such a mess of variables without a set of work instructions?

In welding, one weldor puts in ten passes while another puts in twelve.

And one who just hired in tries it in two, not knowing any different.

He is a person who has never stacked welds before and another has never filled a groove.

And so the story goes.

ISO certs, customers, quality, performance, all require control, documentation and follow up.

Process times and notes can be saved with the file.

If your company is looking into PULSED MIG then I recommend reading of this document. http://www.weldreality.com/pulsed_welding_fundamentals.htm